American Woodworkers’ obsession with weight

Just a few years before the turn of the century (1998), American woodworkers began to be obsessed with weight. A picture appeared in “The Workbench Book” by Scott Landis. The picture showed Rob Tarule, planing away on a reproduction of a “Roubo Bench”. It was weighty and nicely joined – the race was on.

Since then, weight has been the watchword. But, alas, as with so many things in life, we may have allowed ourselves to be mislead. And, I’ll say it now, me too. Three hundred, fifty pounds sounded like a good weight. We appear to have identified weight with stability. And, believe me, brothers and sisters, they’re not the same thing!

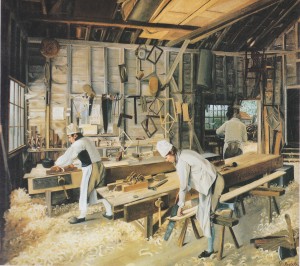

When one looks at the illustrations in “L’art du Menuisier”, it becomes obvious that these were to provide information about how the work was accomplished in Monsieur Roubo’s atelier. Note that there are no dimensions on the benches. The drawings are crudely isometric. And, after looking at the illustration of a half dozen or so benches “fanned out” in the shop, one can only assume that any one of them must have weighed a thousand pounds (1000 lbs.), or so. Also, there seems to be some notion that the method used to join the legs to the bench top is somehow superior. Consider this, timber frames need bracing against wind load. I’ve got to believe that those legs loosened up after a period of time (nail on the crossbracing!). I’m here to tell you that even in professional shops, things get moved around according to the work being done. What professional woodworkers have always been concerned with is stability. Stability and portability. Stability, portability and cost.

Not everyone has the space for a 1/2 ton workbench. Many amateurs and professionals alike work in shops that are rented space, or spaces (basements, attics, corn cribs, etc.) that would make it difficult to position one of these Leviathans.

If one looks back at historic documents (carvings, paintings, drawings) other than Roubo and Deiderot, a different picture begins to appear. Consider the English joiner’s bench. They are now commonly referred to Nicholson benches. But the design was around long before Mr. Nicholson arrived on the scene. He merely documented what was normal in English shops of the day. Some of these benches reached staggering proportions, as the ones used early in the twentieth century for the assembly of wooden air frames.

Scandinavian and German style cabinetmakers benches have long been the standard of both European and American shops. By comparison to anything in the “Roubo” class, they appear puny. But they became the standard for one reason, they fit the needs of the work to be accomplished.

Recently I read a post by Tomas Karlsson at www.hyvelbenk.wordpress.com on a very nice portable workbench with some very interesting features. In case you’re not a follower of the “goings on” at Høvelbenk, you should be. In case you don’t already know, Høvelbenk translates to planing bench. The guys at Høvelbenk investigate all aspects of benches designed for woodworking. IMHO, it is a “must read” blog, along with its “sister” blog, www.skottbenk.wordpress.com.

Another “revival” seems to be in the making. And it’s good news for anyone who is interested in a stable, reasonably portable, professional workbench. Enter the “Moravian”. The design has been around for several hundred years. Easily built, movable and stable, very stable due in large part to the legs be splayed (as opposed to raked). Høvelbenk has a nice post on a Moravian bench built by one of Tomas Karlsson’s students, Anton Nilsson.

Roy Underhill has been offering a class in Moravian Workbench construction, lead by Will Myers at the Woodwrights School.

Before I forget, Jeff Branch has put up some pretty nice drawings of a Moravian bench he plans to build. You can see them at www.jeffbranch.wordpress.com.

I said I’d never build another workbench. But I’ve eaten my words before and when served with some appropriate beverage, they’re not half bad. I think that I would add a center stretcher between the two upper trestle rails. It seems to me that the locator pins holding the top might take some unnecessary but avoidable stresses. I’d probably lag bolt the top. But that’s just me and I’m not going out to jobsites anymore (I’ve become a “woodworker of leisure”, in any number of ways). I think I’d opt for a couple of antique cast iron vises (Oh! My goodness, I think I’ve got a couple of those stashed away, if I can just find them.)

So. If it’s an altar you’re wanting, by all means, go buy yourself a stake truck full of heavy timber and build yourself a Roubo. But if you’re desirous of a stable, portable platform upon which to carry out the manufacture of various assorted parts associated with woodworking projects, think “Moravian.”

And by the way, if you can move this bench around while planing, you probably need to sharpen your irons. There just isn’t enough weight to compensate for dullness.

Explore posts in the same categories: Uncategorized

Tags: Moravian bench, roubo bench

You can comment below, or link to this permanent URL from your own site.

February 6, 2015 at 11:46 pm

Those Morovian benches are simply stunning. I’m currently building a Roubo style bench, but it has more to do with the fact that the aesthetic appeals to me more than anything else.

February 7, 2015 at 1:04 am

I have one of those places with zero room, currently my bench (Paul Sellers Design) is in my living room. It will be moved outside when weather warms up. And at 150 bucks in wood I can use the savings to build some projects. A great post on woodworker economics! Nothing wrong with the Roubo’s they just aren’t for everyone.

February 7, 2015 at 1:56 am

The workbench of Frank Klausz has worked beautifully for me for a few decades. Not so portable but plenty stable.

February 7, 2015 at 8:16 am

Excellent post. Portability, even just around the shop, is underrated. A bit of rubber matting under the legs goes a long way to stop the bench moving while planing and a couple of sand bags over the stretchers keeps the weight low, where it’s useful.

February 7, 2015 at 10:51 am

It’s good there are now some basic questions being posed and generalizations left behind concerning workbenches, thanks D Blaney. Getting at the distinctions between workbench types and their holding devices will begin to settle the din.

Ernest Dubois

February 7, 2015 at 6:30 pm

Thank you for this. Over time, my necessity has gone from portability, to stability, and back again to portability. I look at the Roman and Medieval benches and am impressed more with their lack of mass and low height than anything.

February 7, 2015 at 11:11 pm

Amen to the height issue, George. Most people continue to build their benches much too high for hand tool use. Grandpa’s “rule of thumb” was that the top of the bench should be no higher than the distance from the bottom of your “butt cheeks” or your wrist to the ground. You can saw, you can chisel all day long at a bench that’s the proper height. Make it too high and within 45 minutes most guys will be complaining about pains in their back.

February 7, 2015 at 6:35 pm

Reblogged this on Paleotool's Weblog and commented:

Some great observations on workbenches that are not to be missed. I no longer have a proper shop, so as I continue to minimalize and lighten my possession load, I’m glad to see that the Roubo’s bench isn’t the only game in town. An enormous amount of things I have built, from furniture to boats, houses and tool chests, have been constructed across two well made saw horses.

February 7, 2015 at 7:35 pm

Great post!

The Moravian bench definitely fills a void in the world of workbenches. It has been a bit over three years since I built the first one and I continue to be impressed by it. The dowels in that hold the top work just fine, I have beat the hell out of mine and have not managed to break anything yet! Good luck building yours!

Will Myers

February 8, 2015 at 4:22 am

Thanks for the mention in your blog post. I like the smaller size of the Moravian bench and think the canted legs should offer some stability. I hope to build it later this year.

February 8, 2015 at 3:40 pm

Built myself a European style bench in the mid-80’s (before Landis’ book) have moved it countless times, many repairs and modifications, still working. Nothing better than a tail vise for cutting dovetails, tenons, carving, etc. A decent leg vise is powerful enough to literally crush soft wood, will hold most anything. The alternative is a pair of trestles, couple of planks, hand screws & bar clamps, and enough mass to hold everything in place. I usually need a place to spread out tools that isn’t the workbench surface.

January 3, 2019 at 10:10 am

I could have written this post only not as well. Thanks.

Several years ago I felt a need for a light but stable portable bench to carry in my motorhome. After much thought and “yes but” moments I stumbled across Will Meyers” video of his Moravian bench build. I knew at first sight I had found my answer. I built the first one using Home Depot construction DF. It worked a treat so I built a second using hardwoods and used the first build to replace my very old sharpening bench.

After finishing the second build and using it, I moved an older Roubo bench against the wall (now a junk holding bench) and replaced it with the small portable Moravian. It worked so well I found myself working on the Moravian more than the massive Roubo main bench.

During this time I also tried to figure out the “why’s” that made such a light bench such a pleasure to work on. I also spent time thinking about the build. Bottom line the bench is a good example of great engineering. Each joint is the simplest to make that offers the needed strength and triangles are stronger and more rack resistance than squares.

Cut to the chase, I just finished a third “shop” version of the Moravian bench that has replaced the main Roubo bench. While this bench is larger and with thicker base units, stretchers and slab it is still portable (with help moving the slab) and a joy to work on.

One last comment. We spent the holidays visiting the kids in Houston. A table I had shipped to them was damaged by the freight company. I broke down the portable Moravian and carried it in the bed of the truck with us to Houston, fixed the damaged table and a couple of other things. Once back home the bench stacks neatly in a corner of the shop maybe taking a couple or three sq feet of floor space.

If you can’t tell, I’m a fanboy,

ken

January 4, 2019 at 1:09 am

Thanks for your comment Ken. It’s a great design. And if I ever get back to blogging, i’ll write more about it. My experience has been very similar to yours. You may find this interesting: it may be the heavy Moravian bench that you’ve evolved into: https://www.youtube.com/watch?v=S85mdFccqdw

January 4, 2019 at 3:22 pm

D.B.

Thanks for the link. Not my kind of bench, much too complex, but was interesting to watch and hear his reasoning. If you would like to check out my benches here is a link:https://imaokguy.blogspot.com

ken